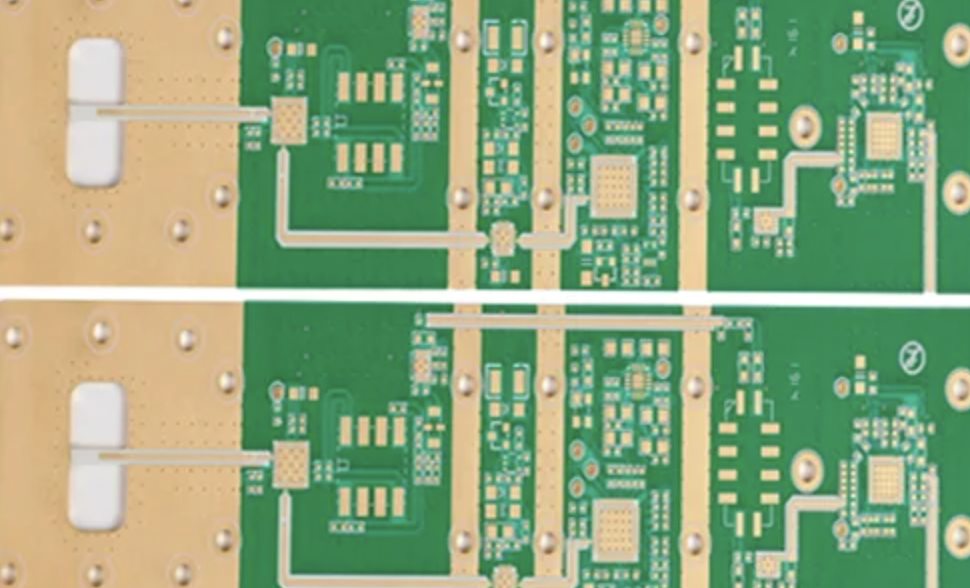

High-frequency Rogers PCBs offer numerous advantages

- High quality ensures low power loss

- Reduced dielectric failure

- Low moisture absorption

- Better thermal management

- Low outgassing, suitable for space applications

- Extremely reliable for use across various industries

- Highly cost-effective for circuit manufacturing